at the moment i have the highest tensile bolt i could get. greater than 10.4 i believe it was.

had to get a internal hex screw head apparently the other they didn't have in such a high tensile.

M10x30mm, i went slightly longer by 5mm (stock from memory is M10x1.5mm 25mm long)

Shim was made to 1.5degrees. By rough guesses it created a camber of approx 8-10mm

http://www.smallparts.com.au/store/partslist/washersselfaligning/washers/wide/1/

I have added alot of front camber. Maybe 4 degree. Similar to http://minkara.carview.co.jp/userid/323248/car/220836/706405/note.aspx

I made the shim like so for the stress dispersion of the anchoring to the hub. Hence the full face shim design rather than some tapered washers.

rough estimate with camber

without camber

Camber - /alignment.html

I just taped the bar stock with electrical tape, so that it could slide a bit on the level. This is good because I want the end of the bar to sit on the lower part of the wheel, not the tire. So I slide the bar so the level can sit on the ground while the bar sits nicely on the lower rim.

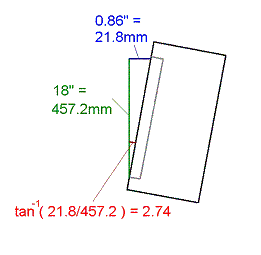

With the level against the wheel, place the digital caliper between the rim and the level (as shown). I really pull the level out about 1.5" or so to start with, and then slowly push it in (which compresses the caliper too) as I watch the bubble in the level. When the bubble is perfectly centered, get the reading from the caliper (0.863in = 21.92mm in the pic).

The camber angle is easily calculated with the formula:

inverse tan( __mm measured / _mm bar length ) = __ deg camber

Example:

inverse tan( 21.92mm / 457.2mm ) = 2.7 deg camber

Or, if you like using inches (I use inches when measuring camber):

inverse tan( 0.863in / 18in ) = 2.7 deg camber

No comments:

Post a Comment