The thickness of the metal that can be removed by grinding from both the cylinder head and the mating cylinder block is limited to 0.2 mm in total.

Gasket surface warp

Standard value: 0.03 mm or less

Limit: 0.2 mm

Grinding limit: 0.2 mm

Cylinder head height (standard value for new part): 131.9 − 132.1 mm

The oil goes around the head stud, hence you need a certain clearance to maintain pressure/oil volume to the head.

OEM Clearance = 1.8mm

Oversized stud clearance = 1.82mm

Diameters:

Head Stud ARP = 9.26mm

OEM Head Stud = 8.14mm

Bored / enlarged oil port hole = 11.08mm

OEM oil port hole = 9.94mm

The Oil Clearance With Boring = 1.82mm

NOTE:

The shaft the oil stud is in has a widened base (block side). Our built head is 11.92mm and the OEM is 11.92. Hence Oil clearance at this point goes from 3.78mm to 2.66m

Mapping the intake ports

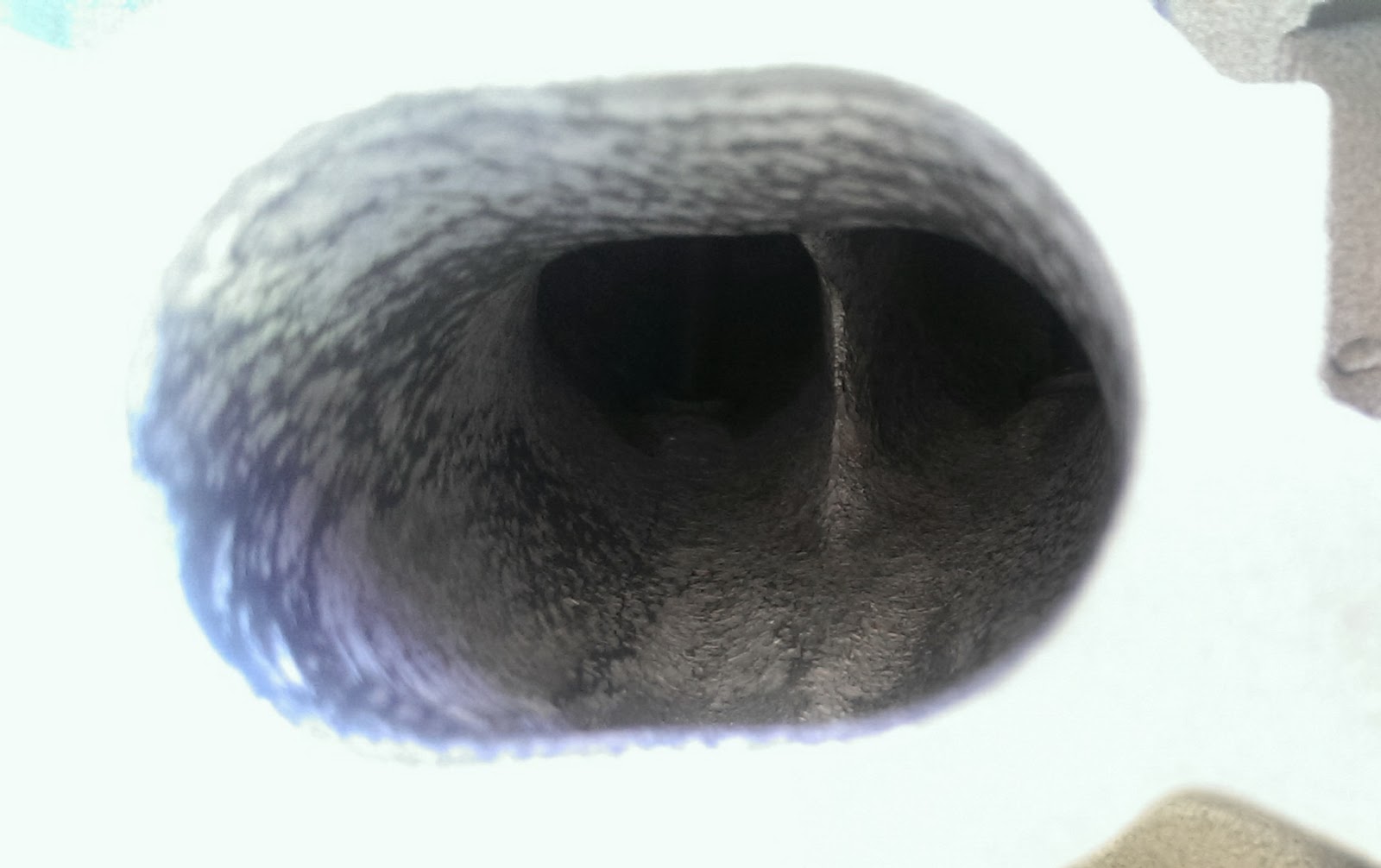

Deepening the oil port due to the head being decked

/4g63t-head-oil-port-mod.html

/oil-port-mod-2-4g63t.html

<- Oil Port Modified Head - You can see there is less lip because of the oversize bore due to the M10 head stud

Stock head stud oil port ->

Head Height

Standard value: 0.03 mm or less

Limit: 0.2 mm

Grinding limit: 0.2 mm

Cylinder head height (standard value for new part): 131.9 − 132.1 mm

OEM Head = 132.06mm

Machined Head = 131.98mm

More Info

Check the cylinder head gasket surface for warp using a straightedge and thickness gauge. If the surface is warped beyond the limit, grind the

surface for rectification.

When reusing a cylinder head bolt, check that its nominal length (shank length) is not greater than the limit. If the limit is exceeded, replace the bolt.

Limit: 103.2 mm

Install each valve spring with the painted end toward the rocker arm.

Tighten the bolts to 49 ± 2 N⋅m in the indicated sequence.

4. Loosen all the bolts completely.

5. Tighten the bolts again to a torque of 20 ± 2 N⋅m in the indicated sequence.

If the tightening angle is smaller than 90°, proper fastening performance could not be assured. Be sure to respect that angle.

• If the bolt is tightened to an angle greater than the specified angle, loosen the bolt com-pletely and then retighten it beginning with the first step.

6. Make paint marks on each bolt’s head and on the cylinder head.

7. Turn the bolts 90° in the tightening direction and in the indicated sequence.

8. Give another 90° turn in the tightening direction to each bolt, making sure that the paint mark on the bolt head and that on the cylinder head are on the same line.

Port Mapping

Area of an Ellipse - Area of an ellipse can be calculated when we know the length of the semi-major axis (r1) and length of the semi-minor axis (r2).

Area of an Ellipse = pi x r1 x r2

Intake Widths - OEM Port

(1) 36.82

(2) 36.68

(3) 37.66

(4) 18.94

(5) 18.86

Intake Widths - Hand Porting

(1) 38.46

(2) 37.4

(3) 38.7

(4) 20.08

(5) 19.86

Exhaust Widths - OEM Port

(1) 37.6

(2) 38.46

(3) 41.9

(4) 21.32

(5) 20.92

Exhaust Widths - Hand Porting

(1) 40.8

(2) 39.14

(3) 42.76

(4) 21

(5) 21.82

Exhaust Heights - OEM

(1) 20.86

(2) 19.46

(3) 17.86

Exhaust Heights - Ported

(1) 23.66

(2) 20.7

(3) 18.04

Hi iam fitting ARP bolt to my colt czt engine ....bit confused on wot size to bore the hole in the head ????thanks paul

ReplyDelete